Huachen Refractory

Magnesite Chrome brick manufacturer

Phone/WhatsApp

008618939512185

Email :info@hcrefractory.com

www.magnesitechrome.com/

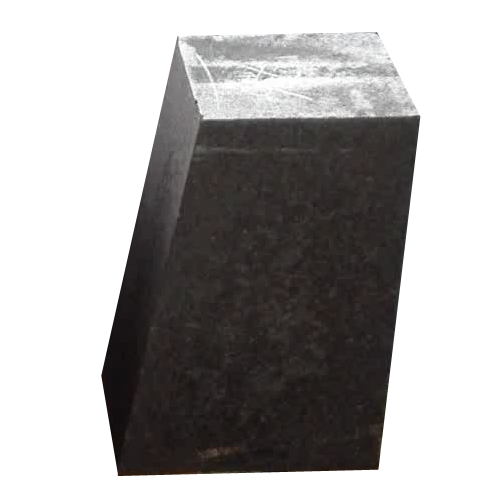

Fused cast magnesite chrome brick

Other name: Fused cast MgO-Cr2O3 brick

Model Number: ERMG-12, ERMG-16, ERMG-20

Certification: ISO 9001-14001

Minimum Order Quantity: 10 MT

Fused cast magnesite-chrome brick

Description:

The fused-cast magnesite-chrome brick has a peculiar resistance to the damage of slag penetration. Since it is a dense frit made by melting, pouring and cooling, the slag can only be eroded on the outside of the brick without a large number of signs of osmotic (this has been proved by the section of the cast magnesite-chrome brick after use). Although magnesite-chrome brick is difficult and expensive to produce, it is still used in the key parts of non-ferrous smelting furnaces in developed countries, and it has an irreplaceable role in other refractory materials.

Advantages:

Dense,

large pores and isolated, high strength, corrosion resistant, good

thermal shock to resistance, high refractoriness under load

Application:

Slag ingress, corrosion, wear and erosion area, non-ferrous metal smelting flash furnace reaction tower side wall and sedimentation tank slag line parts, continuous operation furnaces

Fused cast magnesite-chrome brick physical and chemical

| MgO min% | 50-60 |

| Cr₂O₃ min% | 15-20 |

| SiO₂ MAX% | 1-4 |

| Apparent porosity MAX % | 5-15 |

| Bulk Density g/cm³ | 3.7 |

| Cold Crushing Strength Mpa ≥ | 80 |

| Refractoriness under load of 0.2Mpa(℃) | 1700 |

| Therm.Exp (1000℃) MAX % | 1.5 |